Production Quality Analysis Using Vision Data

Implemented vision systems perform inspection and send results using standardized communication protocols

Custom application collects and organizes the inspection results for long term database storage

Results are stored and updated between local and cloud database

Inspection results are accessed from any application such as the workstation, a webpage, and even your mobile device

Introducing the flexibility to store any information from existing inspection systems, even images. Customized to fulfill your inspection needs, years of inspection results can be safely stored in a database.

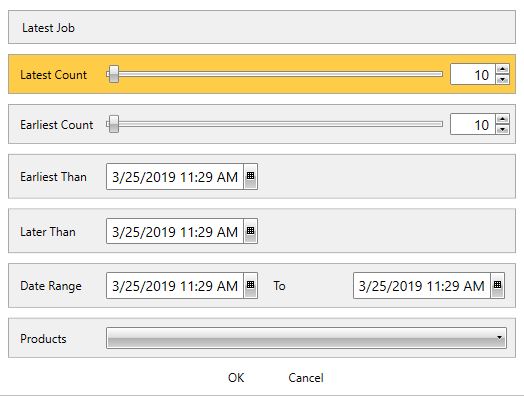

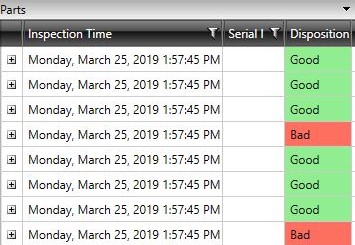

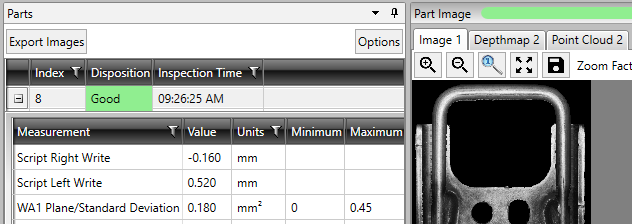

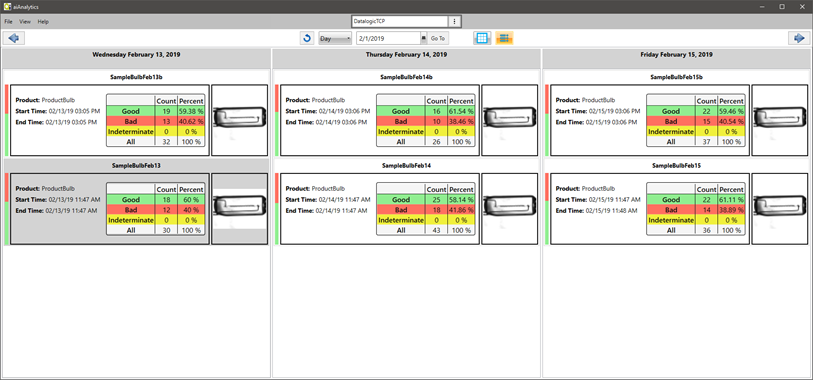

All inspection results are easily accessible within the viewer application. Viewings are customizable to show relevant information, and jobs can be searched by date and product name.

Inspection images are automatically linked to their corresponding part and stored directly in the database in a compressed format. Images can be auto-deleted after a specified amount of time has passed, freeing space for more results.

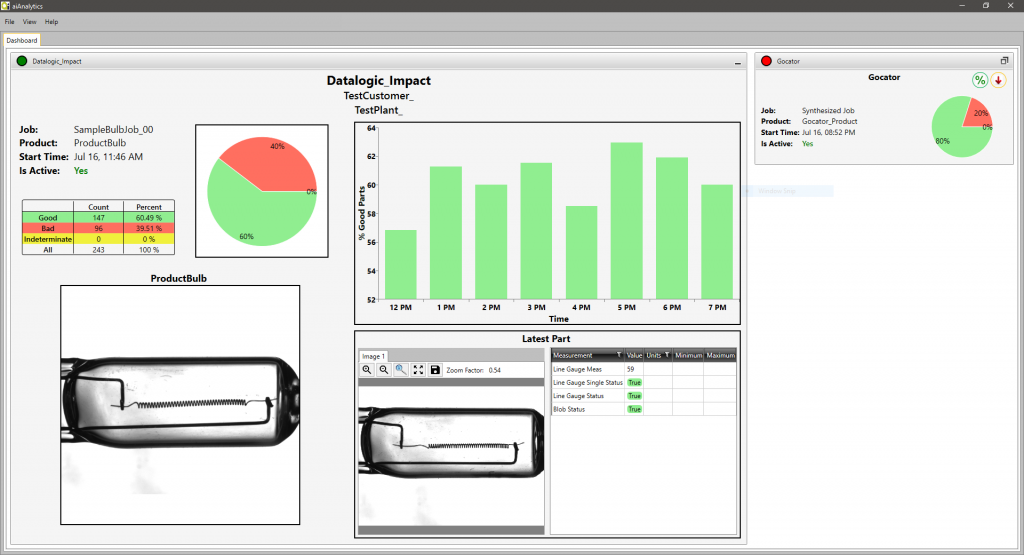

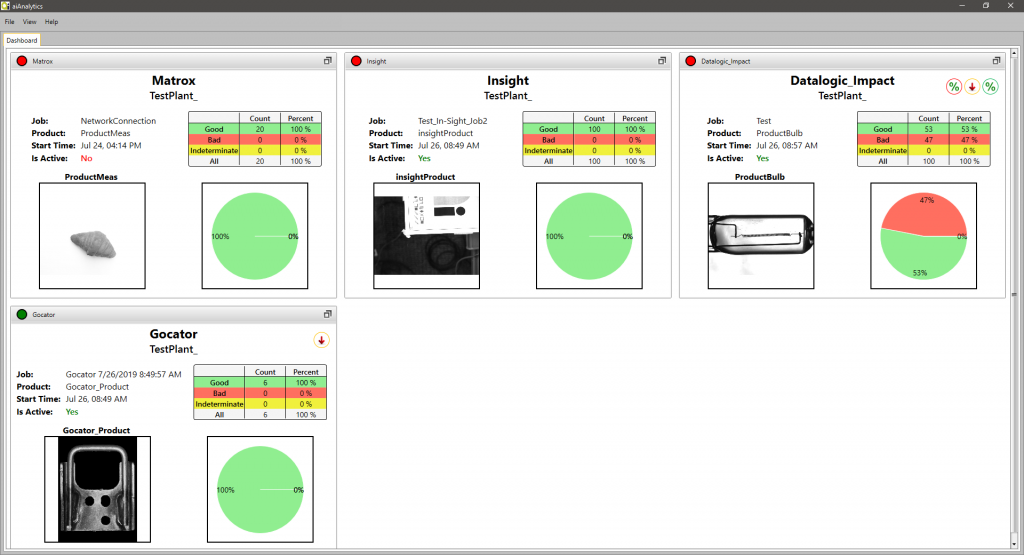

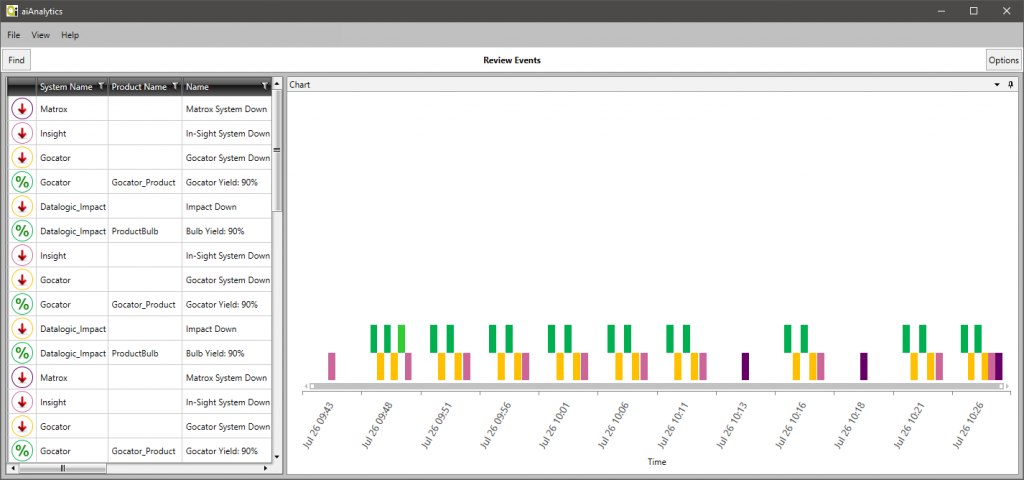

The Dashboard offers a live view of all connected systems. Information about the latest part, quality of the job per hour, and general job information is accessible from the home page of the viewer application.

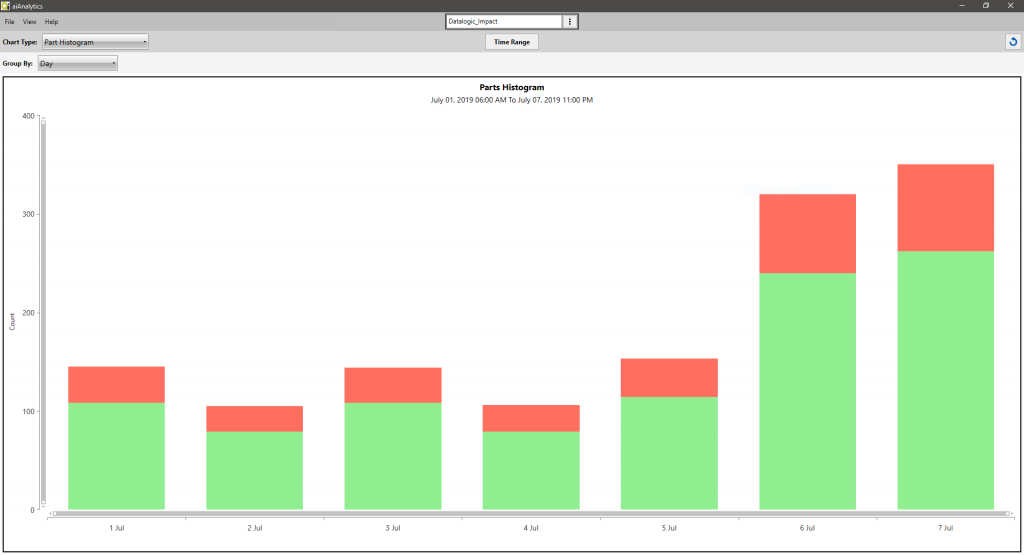

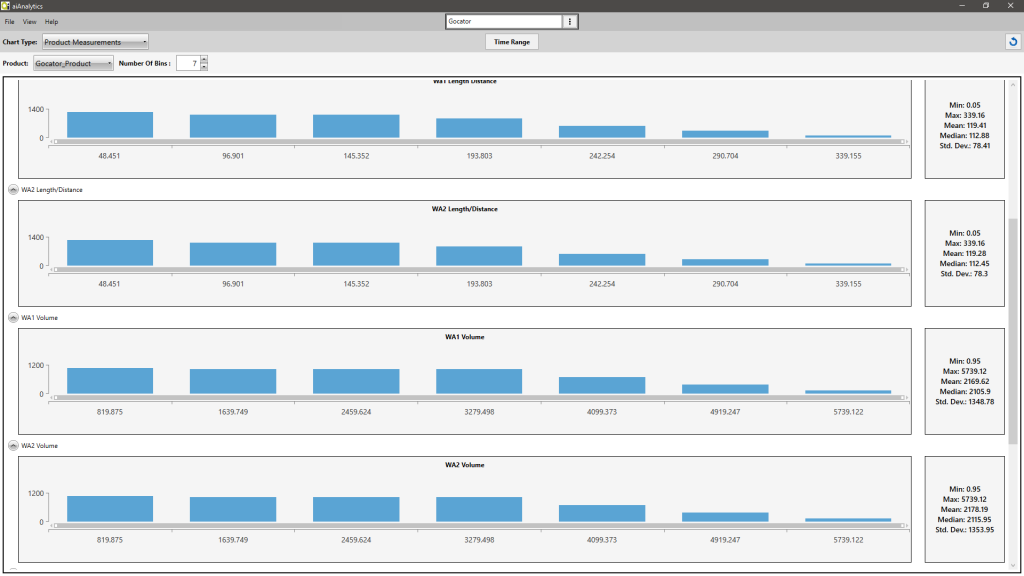

Data about jobs, parts inspected, product measurements, and yield percentage gathered over periods of hours, shifts, days, weeks, and months are plotted to.

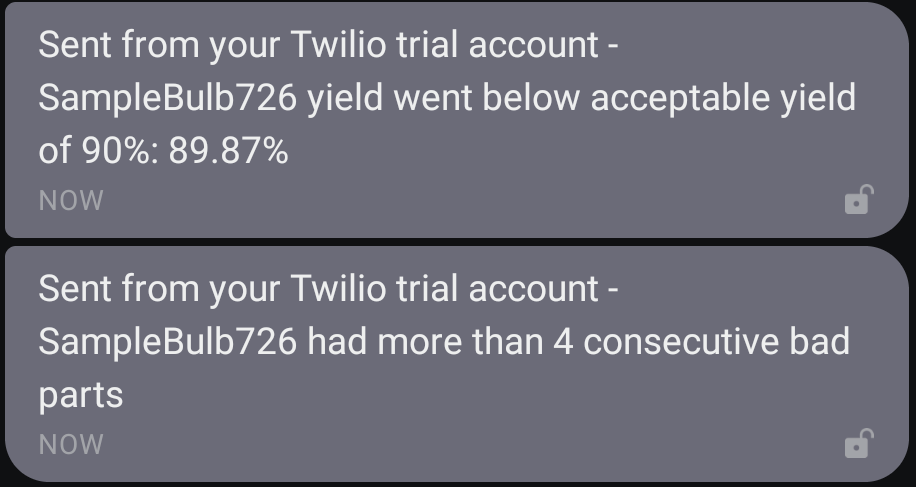

Get notifications on how your lines are running. Alerts about product yield, consecutive bad parts, and downtime can be sent via text or email.

Review previous jobs by sorting them into days or shifts. Selecting a job will lead back to the reviewer page for more details.

Data communication utilizing widely implemented protocols such as TCP/IP, Ethernet/IP, Modbus, and more.

All results are sent using a standardized format designed to meet your needs. Any information, from measurements to classification, can be archived. This ensures compatibility with many industry-leading systems and devices.