Custom Vision Solutions

Active Inspection builds turnkey custom vision solution for unique requirements. We are partnered with all major supplies of machine vision components. This allows us to build the best and least cost solution by selecting appropriate camera, optics, lighting, and development environment.

- Line scan, area, and laser profiler applications

- Concurrent 3D and color inspection using

- Chromasens 3DPIXA stereoscopic line scan cameras

- Custom machine vision processing

- Intuitive user interface for desktop, web, and mobile devices

- Database storage of inspection results and images

- Detailed PDF, Excel, and XML reports

- Integration with the plant system via PLC, OPC, and custom interface

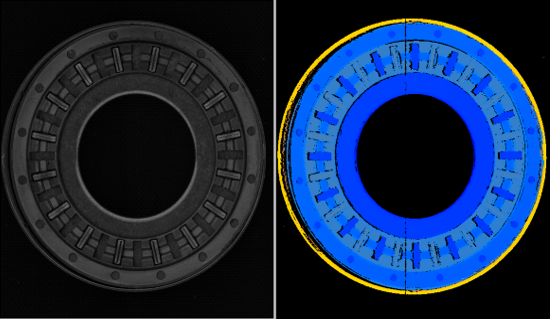

Steel Bearing Inspection

- Camera: 3DPIXA Dual

- Resolution: 15 µm x 15 µm x 3 µm

- Part Size: 4” x 4”

- Inspection Rate: 80 parts/minute

- Defects Detected:

- Press defects

- Broken flange

- Missing rollers

- Scratches

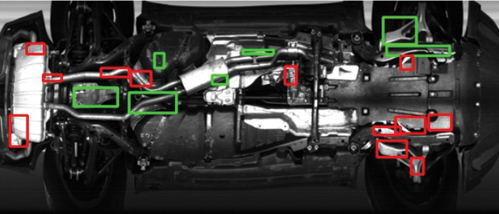

Under Vehicle Surveillance System

- Camera: Color area camera, 1000 fps

- Vehicle Speed: 35 miles/hour

- Vision Tasks:

- Stitch images

- Anomaly detection

Microstructure Inspection

- Camera: 16K Line scan

- Resolution: 1 µm x 1 µm

- Part Size: 10 mm x 10mm

- Vision Tasks:

- Count elements

- Detect missing elements

- Shape analysis

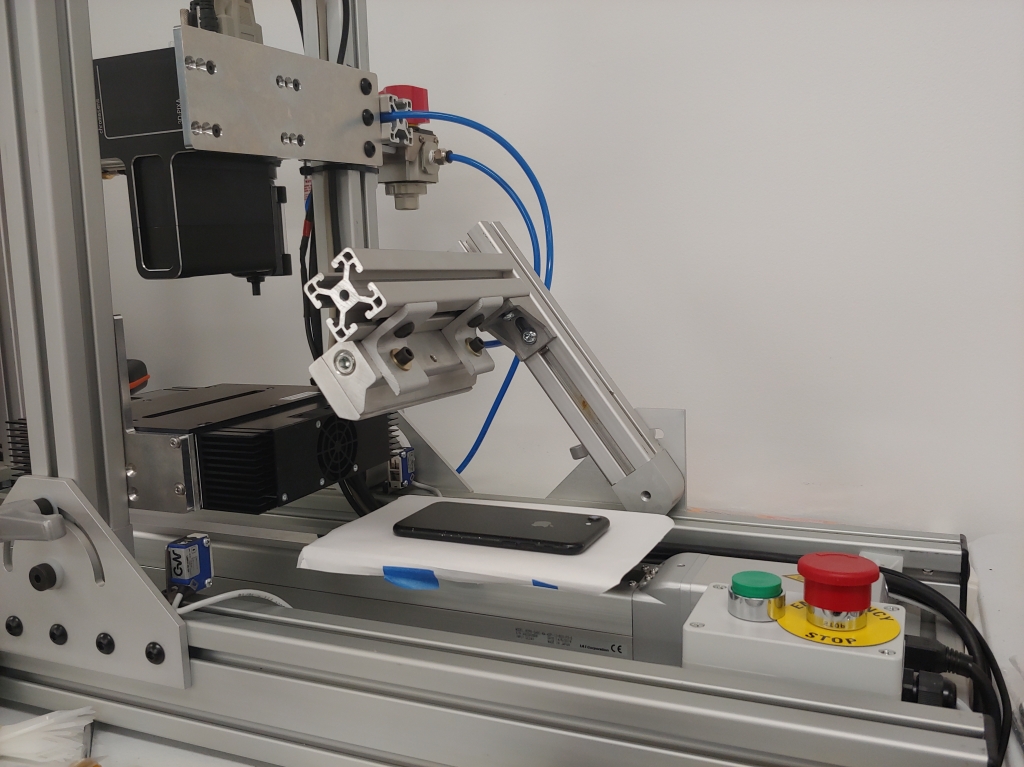

Color and 3D Glass Surface Inspection

- Camera: 3DPIXA and 3 area scan cameras

- Resolution: 30 µm x 30 µm x 10 µm

- Part Size: 6” x 4” x 0.5”

- Vision Tasks:

- Inspect for surface 2D and 3D defects

- Inspect sides for scratches

- Perform automatic grading